The Case for Polyurethane

Unique Material

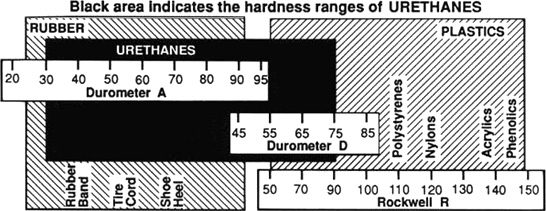

Polyurethane is a unique material that offers the elasticity of rubber combined with the toughness and durability of metal. Because urethane is available in a very broad hardness range (eraser-soft to bowling-ball-hard), it allows the engineer to replace rubber, plastic and metal with the ultimate in abrasion resistance and physical properties.

Polyurethane can reduce plant maintenance and OEM product cost. Many applications using this ultra-tough material have cut down-time, maintenance time and cost of parts to a fraction of the previous figures.

Urethanes have better abrasion and tear resistance than rubbers, while offering higher load bearing capacity. Compared to plastics, urethanes offer superior impact resistance, while offering excellent wear properties and elastic memory.

Urethanes have replaced metals in sleeve bearings, wear plates, sprockets, rollers and various other parts, with benefits such as weight reduction, noise abatement and wear improvements being realised.

Advantages

Advantages of Polyurethane

- Abrasion resistant

Parts made of polyurethane will often outwear other materials by a margin of 5-50:1 when severe abrasion is a factor. It has been proven to be vastly superior to rubber, plastics and metal in many applications. - Oil and solvent resistant

Polyurethane has excellent resistance to oils, solvents, fats, greases and gasoline. - Load bearing capacity

Polyurethane has a higher load-bearing capacity than any conventional rubber. Because of this characteristic, it is an ideal material for load wheels, heavy-duty couplings, metal-forming pads, shock pads, expansion joints and machine mounts. - Tear resistant

Tear-strength ranges between 500-100 Ibs./linear inch, which is far superior to rubbers. As a result, urethane is often used as drive belts, diaphragms, roll covers, cutting pads, gaskets and chute liners. - Weather resistant

Polyurethane has outstanding resistance to oxygen, ozone, sunlight and general weather conditions. - Excellent noise abatement properties

The hard urethanes are now being used as gears in products where engineers desire sound reduction. The soft urethanes are used to replace rubbers for improved sound/vibration dampening. - Flex-Life

Most formulations offer extremely high flex-life and can be expected to outlast other elastomer materials where this feature is an important requirement. Dust boots, bellows, diaphragms, belts, couplings and similar products are made from urethane for this reason. - Electrical properties

Polyurethane has excellent electrical insulating properties and is used successfully in many moulded wire and cable harness assemblies. - Heat and cold resistant

Continuous use above 107°C/225°F is not recommended nor is urethane recommended in hot water over 79°C/175°F. At low temperatures, polyurethane will remain flexible down to -68°C/-90°F. A gradual stiffening will occur at -18°C/0°F but will not become pronounced until much lower temperatures are obtained.

Typical Polyurethane Products

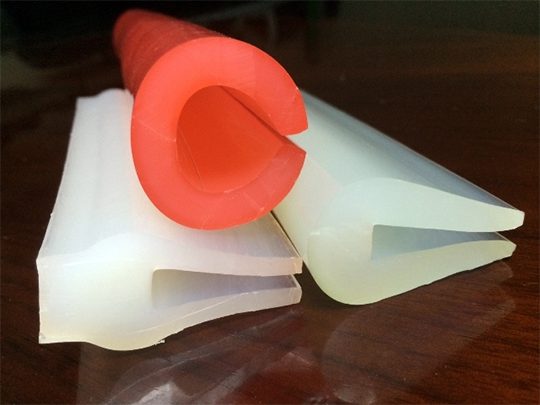

| Precision-Cast Sheets | Cast sheets are ideal for fabrication into a wide variety of products. |

| Fabric-Backed Sheets | Standard sheets are available integrally cast onto duck cloth (.048″ thick), permitting easy cementing to metal or other surfaces. This composite converts effectively to large roll coverings or chute and bin liners. Bond strength between the fabric and the urethane is excellent, and there is no strikethrough to the exposed side of the fabric. |

| Bars | Bar stock is popular for metal forming uses. The precise size eliminates the need for a matched female die. The material becomes the contact surface in forming, bending or shaping metal without scratching or marring the finished product. Bar stock is also used as press-brake pads, bumper pads and wear strips, and is machined into a great variety of prototype parts. |

| Rods | Cast rods are used for guide, drive and pinch rollers and outwear conventional rubber rollers 20 to 1. They are excellent for bulge forming. Rod stock is used for prototype parts like gears, bearings and bushing, and is easily machined to close tolerances. |

| Tubes | Cast tube stock makes excellent roll covers when press fitted over metal cores. They are also converted into gaskets, seals and rings. Tubes are well suited for prototype parts |

Typical Polyurethane Applications

- Wear strips

- Bumpers

- Gears

- Bellows

- Machinery mounts

- Cutting surfaces

- Sound-dampening pads

- Gaskets

- Seals

- Rollers

- Roller covers

- Sandblast curtains

- Diaphragms

Comparison of Polyurethane to Other Non Metallic Materials

| COMPOUND = | MP300 | MP600 | MP750 | MP850 | MP900 | MP950 | MP160 | MP175 | ||

| DUROMETER = | 30A | 60A | 75A | 85A | 90A | 95A | 60D | 75D | ||

| TYPICAL APPLICATIONS | REPLACES | KEY PHYSICAL PROPERTIES | ||||||||

| BUMPER PADS | Rubber | X | X | Bashore Resilience | ||||||

| CUTTER BARS | Wood, UHMW | X | X | Tear; Compression /Deflection | ||||||

| BUSHINGS | Rubber, Metal | X | X | X | X | Abrasion, Tear | ||||

| TUMBLER LININGS | Rubber | X | Bashore Resilience | |||||||

| ISOLATION VIBRATION | Rubber | X | X | X | Resilience; Compression /Deflection | |||||

| CUTTING SURFACES | Wood, UHMW | X | X | X | Tear; Compression, Deflection | |||||

| DIE CUTTING PADS | Wood, UHMW | X | X | X | Tear; Compression, Deflection | |||||

| WEAR PADS | UHMW, Metal | X | X | Tear; Compression, Deflection | ||||||

| IDLER ROLLERS | UHMW, Metal | X | X | X | Tear; Compression, Deflection | |||||

| SQUEEGEES | Rubber | X | X | X | Tear; Solvent Resistance | |||||

| FORK LIFT TIRES | Rubber | X | X | X | Heat Build Up; Resilience | |||||

| FORK LIFT TIRES | Rubber | X | X | X | Heat Build Up; Resilience | |||||

| PRINTING ROLLS | Rubber | X | X | Solvent Resistance, Compression Set, Abrasion | ||||||

| OIL PIPELINE PARTS | Rubber, Metal | X | X | X | X | Oil and Abrasion Resistance | ||||

| HYDRAULIC SEALS | Rubber | X | X | Oil Resistance; Compression Set | ||||||

| GRAIN SHOOT LININGS | Rubber | X | Sliding Abrasion | |||||||

| OFFICE EQUIP ROLLERS | Rubber, Plastic, Metal | X | X | X | Tear, Abrasion Resistance | |||||

| ELEVATOR WHEELS | Rubber | X | X | X | Compression Set; Compression /Deflection; Heat Build Up | |||||

| PAPERMILL ROLLS | Rubber, Metal | X | X | X | X | Heat Build Up; Hydrolysis Resistance | ||||

| GASKETS | Rubber, Cork | X | X | X | X | X | X | Compression Set; Chemical Resistance |

Polylok’s Polyurethane Expertise

Polylok Products has worked with polyurethane for over 30 years. We understand how it works and how to get the best results for our customers.

Our extensive knowledge and experience are applied to each polyurethane product we design and manufacture. We know what works and what doesn’t work!

We pride ourselves on the quality of our workmanship and we guarantee you’ll be satisfied with our products and our service.

Call us for a quote or to discuss your specific needs.